200-500 TPD Large Flour Milling Plant

Our large scale flour milling equipment has a production capacity of 200-600 tons/day. These machines are mainly installed in reinforced concrete buildings or steel structural plants, which are generally 5-to 6-storey high (including the wheat silo, flour storage house, and flour blending house).

Our flour milling solutions are mainly designed according to the American wheat and Australian white hard wheat. When milling a single kind of wheat, the flour extraction rate is 76-79%, while the ash content is 0.54-0.62%. If two kinds of flour are produced, the flour extraction rate and ash content will be 45-50% and 0.42-0.54% for the F1 and 25-28% and 0.62-0.65% for the F2. Specifically, the calculation is based on the basis of dry matter. The power consumption for the production of one ton of flour is no more than 65KWh on normal conditions.

The PLC system is adopted for controlling all the machines. Once a fault is detected, the PLC intelligent system will respond accordingly according to the diagnosis to minimize influence of the problems. The responds may include sound-light alarm, material feeding cutting-off, and so on.

Functions of PLC control system

1. Displaying the real time flow quantity of raw wheat, clean wheat, flour, inferior flour and bran.

2. Displaying the yield rate of flour, inferior flour and bran.

3. Displaying the flow quantity during a certain period of time of raw wheat, clean wheat, flour, inferior flour, bran, and so on.

4. Recording and displaying the power consumption during a unit time interval.

5. Checking the history material flow quantity.

6. Fault alarming, recording and printing.

7. Generating and printing the production reports on a shift, day or month basis.

8. Managing the blending formulas by which flour blends can be precisely produced.

We can install all the system for you according to the equipment list. But we need customers to provide water, three phase power, crane, forklift, oxyacetylene welding machine, electric welding machine for the installation project.

We will send 2-3 installation and electric engineers to help with the system installation, equipment test run, and operational training. During all the system's service life, we can provide technical support.

Related machinery

Conveying Equipment

Cleaning Equipment

Milling Equipment

Blending and Packing Equipment

Aspiration and Pneumatic Transferring Equipment

Equipment parameter

| Model | Capacity (MT/day) | Roller Mill Model | Installation Power (kW) | Worker per Shift | Water Consumption (t/d) | Space L×W×H (m) |

| CTWM-200 | 200 | Pneumatic / electrical | 450-500 (Without blending) | 6-8 | 10 | 48×11.5×28 |

| CTWM-300 | 300 | Pneumatic / electrical | 650-700 (Without blending) | 8-10 | 15 | 56×12×28 |

| CTWM-400 | 400 | Pneumatic / electrical | 800-850 (Without blending) | 10-12 | 15 | 68×12×28 |

| CTWM-500 | 500 | Pneumatic / electrical | 950-1000 (Without blending) | 10-12 | 25 | 76×13.5×30 |

60-150 TPD Compact Flour Milling Plant

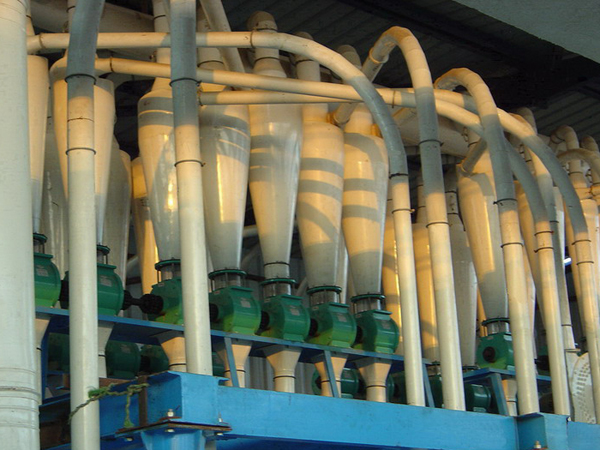

Our machines for the compact flour milling plant are specially designed and installed together with the steel structure support. The main support structure comprises three levels: the roller mills are located on the first floor; the sifters are installed on the second floor and the cyclones and pneumatic pipes are on the third floor. The materials from the roller mill are lifted to the cyclones by the pneumatic transferring system and then discharged onto the sifters. The screened flour will then entered the flour milling machine. The whole mill can be installed in a warehouse. We can provide personalized designs to meet your specific requirements.

Our products have been widely used in small and middle wheat mills and farms in many developing countries. This impact flour milling solutions are especially suitable for the fresh investors in wheat processing industry.

Feature

1. The production capacity varies from 60MT to 150MT wheat per day. You can make the choice as per your requirements.

2. The compact design can save you much area and the corresponding cost can be reduced.

3. The low capital investment and low power consumption means low product cost.

4. Our reliable and productive machines coupled with excellent design can bring you high quality flour and high yield.

Note

1. The detailed cleaning and milling flow sheets could be designed following customer' s special requirements and the plant's location.

2. The wheat silos and flour and bran warehouse are not included in the above solutions.

3. For more technical and price information, you can directly contact us.

Related machinery

Conveying Equipment

Cleaning Equipment

Milling Equipment

Blending and Packing Equipment

Aspiration and Pneumatic Transferring Equipment

Equipment parameter

| Model | Capacity (MT/day) |

Roller Mill Model | Sifter Model | Cleaning Process | Milling Process | Installation Space L×W×H (m) |

| CTWM-60 | 60 | manual | T win sifter | 3-sifting, 2-scrouring 2-destoning, 1-washing | 4-breaking, 5-reducing 1T | 35×8×11 |

| CTWM-80 | 80 | pneumatic | plansifter | 4-breaking, 6-reducing 1S. 1T, 2P | 38×10×11 | |

| CTWM-100 | 100 | pneumatic | plansifter | 3-sifting, 2-scrouring, 2-destoning, 1-dampening | 42×10×11 | |

| CTWM-120 | 120 | pneumatic | plansifter | 5-breaking, 8-reducing 1S. 1T, 4P | 46×10×11 | |

| CTWM-150 | 150 | pneumatic | plansifter | 50×10×11 |

English

English العربية

العربية Русский

Русский Français

Français Português

Português Español

Español