Entoleter

The entoleter is definitely a must for a flour milling factory. Our high quality insect destroyer for flour mill is applied before flour packing or its transferring to the bin, to effectively reduce the insects and their eggs. The high-speed rotating also leads to perfect impacting performance. Thus the flour storage endurance is greatly enhanced. In addition, our entoleter can be also used as a bran finisher to process the granular materials or intermediate materials, detaching the endosperm on the bran.

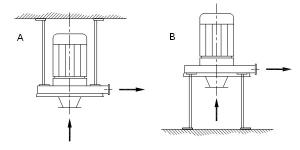

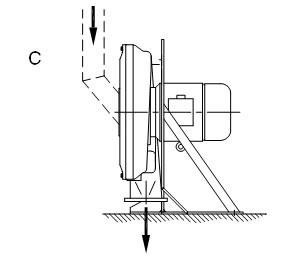

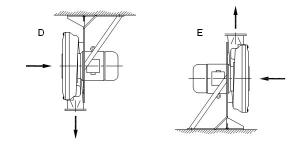

Installation drawing

-

Installation in a suction

pneumatic line -

Installation in

gravity spouting - Installation in blowing line

| Type | Capacity | Power | Rotary Speed | Rotor Diameter | Shape Size | |

| t/h | kW | r/min | mm | L×W×H (mm) | ||

| 1.8 | 4 | 2900 | ф430 | 800×520×805 | ||

| 2.9 | 5.5 | 2900 | ||||

| 4.7 | 7.5 | 2900 | ||||

| 4.5 | 15 | 2900 | ф510 | 800×690×850 | ||

| 6.2 | 18.5 | 2900 | ||||

| 8.8 | 22 | 2900 | ||||

| 11-15 | 30 | 2900 | ф510 | 1081×800×850 | ||

| 15-18.5 | 37 | 2900 | ||||

| 18-23 | 45 | 2900 | ||||

Note : The asterisk (*) means Double Side.

Inquiry Form

Other products

English

English العربية

العربية Русский

Русский Français

Français Português

Português Español

Español